Acrylic Sheet in Malaysia A Comprehensive Guide to Types, Uses, and Advantages

In this comprehensive guide, we will delve into the world of acrylic sheets in Malaysia, exploring their various types, diverse applications, and the numerous advantages they offer. As a leading authority in acrylic sheet technology, we aim to provide you with valuable insights and knowledge that will help you make informed decisions regarding the use of acrylic sheets in your projects.

Introduction to Acrylic Sheets

Types of Acrylic Sheets

Extruded Acrylic Sheets

Extruded acrylic sheets are manufactured through a process known as extrusion, where the acrylic material is pushed through a die to form a continuous sheet. These sheets are cost-effective and available in a wide range of colours and thicknesses, making them suitable for applications such as signage, displays, and protective barriers.

Cast Acrylic Sheets

Cast acrylic sheets are produced by pouring liquid acrylic into a mould and allowing it to cure. This manufacturing method results in sheets with superior optical clarity and better chemical resistance compared to extruded sheets. Cast acrylic sheets are commonly used in high-end applications such as architectural glazing, museum displays, and artistic installations.

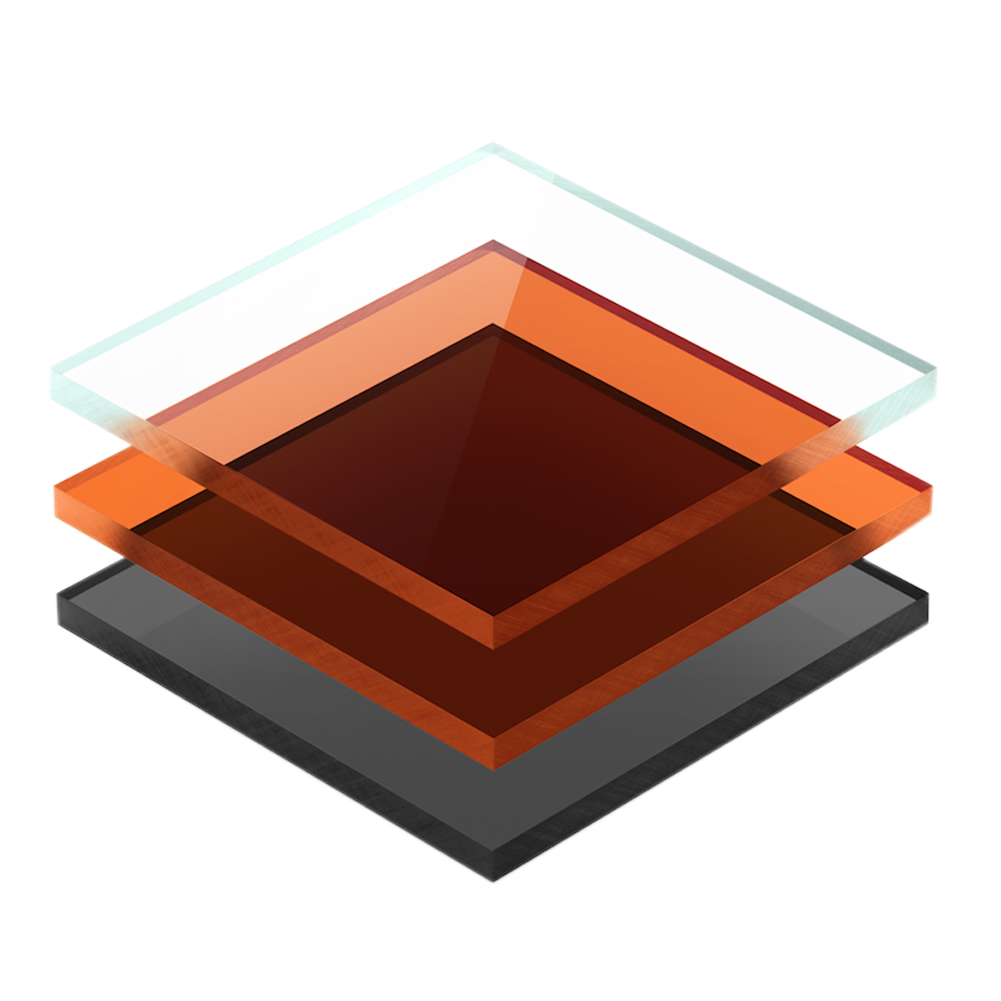

Coloured Acrylic Sheets

In addition to clear acrylic sheets, a wide array of coloured acrylic sheets is available in the market. These sheets come in various vibrant hues and can be used to add a splash of colour to architectural elements, interior design features, and artistic projects.

Textured Acrylic Sheets

Textured acrylic sheets feature unique surface patterns, such as frosted, matte, or stippled finishes. These textures not only enhance the visual appeal of the sheets but also offer functional benefits like light diffusion and improved scratch resistance. Textured acrylic sheets find applications in privacy screens, light fixtures, and decorative panels.

Uses of Acrylic Sheets

Architectural Applications: Acrylic sheets are extensively used in architectural applications due to their versatility and aesthetic appeal. They can be used for windows, skylights, canopies, and interior partitions. Acrylic sheets are also popular for creating unique architectural features, such as curved walls, domes, and intricate facades.

Signage and Displays

The clarity and durability of acrylic sheets make them an ideal choice for signage and display applications. They can be easily fabricated into various shapes, allowing for eye-catching signs, point-of-purchase displays, and exhibition stands. Acrylic sheets also offer excellent light transmission, enhancing the visibility of printed graphics and messages.

Automotive Industry

Acrylic sheets are widely utilized in the automotive industry for their lightweight nature and impact resistance. They are used for headlights, taillights, instrument clusters, and interior trim components. Acrylic sheets can be tinted, providing privacy and sun protection for automotive windows.

Furniture and Interior Design

Acrylic sheets have gained popularity in furniture and interior design due to their modern aesthetic and versatility. They can be used for tabletops, countertops, shelving, and decorative panels. Acrylic sheets can mimic the look of glass while offering better impact resistance, making them a practical choice for both residential and commercial applications.

Medical and Scientific Applications

Acrylic sheets possess excellent optical properties and chemical resistance, making them suitable for medical and scientific applications. They are used for medical equipment, laboratory enclosures, and protective barriers. Acrylic sheets are also preferred for aquariums and aquatic displays due to their exceptional transparency.

Advantages of Acrylic Sheets

Clarity and Transparency

Acrylic sheets offer exceptional clarity, surpassing that of glass. Their high light transmission properties allow for maximum visibility, making them perfect for applications where transparency is crucial.

Durability and Impact Resistance

Acrylic sheets are significantly more durable than glass and other plastic materials. They exhibit excellent impact resistance, making them less prone to breakage. This durability ensures a longer lifespan and reduced maintenance costs.

Lightweight

Acrylic sheets are lightweight, which makes them easier to handle and install compared to glass. This advantage is particularly important in applications where weight plays a significant role, such as transportation vehicles and aircraft.

Weather Resistance

Acrylic sheets have excellent weather resistance, making them suitable for both indoor and outdoor applications. They are resistant to UV radiation, preventing yellowing and degradation over time.

Easy Fabrication

Acrylic sheets can be easily cut, drilled, and thermoformed, allowing for a wide range of design possibilities. They can be shaped into intricate forms and customized to meet specific project requirements.

Conclusion

Acrylic sheets are a versatile and highly sought-after material in Malaysia, catering to a wide range of industries and applications. Their numerous types, extensive uses, and notable advantages make them a preferred choice for architects, designers, and manufacturers alike. With their exceptional clarity, durability, and aesthetic appeal, acrylic sheets continue to shape the future of modern design and construction.